"Why are plastic molds so expensive?"This is probably the voice of most customers!But in author's opinion, All of this is traceable.

1.Customized products

Plastic molds are customized products, not ordinary standard parts.2.Working hours

A set of molds requires a large number of personnel to participate from material purchase, transportation, to design and manufacturing.The difficulty of the product structure determines the difficulty of mold processing.The more complex the mold processing, the more manpower and material resources are spent.3.Material cost

Then there is the material cost, which is divided into two parts, the base material and consumables of the mold, and the consumables of the tools and props during processing.The cost of mold steel used in plastic molds is an important factor affecting the price of plastic molds.Take the mold designed by OmkBoxes as an example.Because molds require high precision, the size tolerance of the mold is generally required to be plus or minus 0.01mm, and some important tolerances will require plus or minus 0.005mm, or even plus 0.005mm.Therefore, not only the mold base material is required to have good machinability, but also high-precision tools and high-performance electrodes for electrical discharge machining are required.

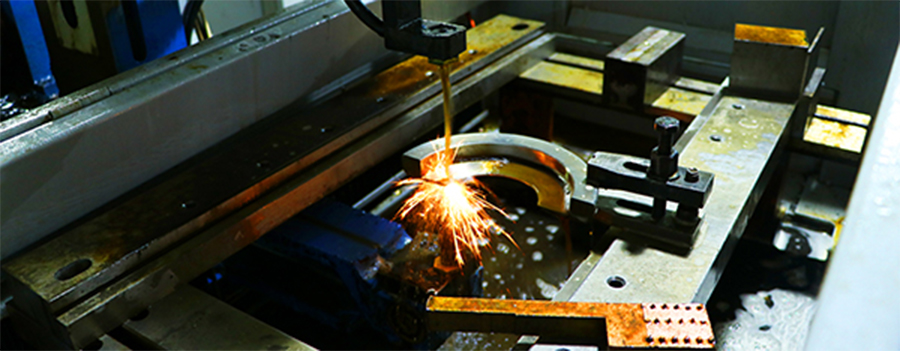

Generally, the material used for important parts is NAK80, a 20X80X120mm NAK80 steel is about 60~80 dollars, and a 10X30X80mm CuW electrode base material for electrical discharge machining is about 90~110 dollars.Then the tool for processing, the unit price is more than 30 US dollars.The mold core needle, thimble and other parts that need to be purchased are about 600-1500 US dollars.In addition, there are copper wires consumed by wire cutting, and sometimes it may fail, so you have to start over so that the material cost is very high.4.Equipment cost

A machining center for processing costs US$250,000, an electrical discharge machine and a wire-cutting machine each cost about US$150,000, plus various measuring equipment, such as a high-precision measuring needle (for diameter measurement). It costs 90~110 dollars, then from 0.1~3mm, every 0.01mm is equipped with one, 3mm~10mm is equipped with every 0.025, and then there is a high-precision gauge block so that it can be calculated by measuring equipment alone. After buy a few machining centers, although these are not disposable items, as the frequency of use increases, regular replacement and maintenance are also necessary. However, according to the amount of this equipment, the equipment cost of manufacturing molds is also evident.

There are many factors that affect the cost of plastic molds, not just the four points mentioned above.Therefore, when considering choosing a plastic mold supplier, it is recommended to choose an experienced plastic mold manufacturer. This may help you optimize the cost of plastic molds.