1. Plastic parts analysis

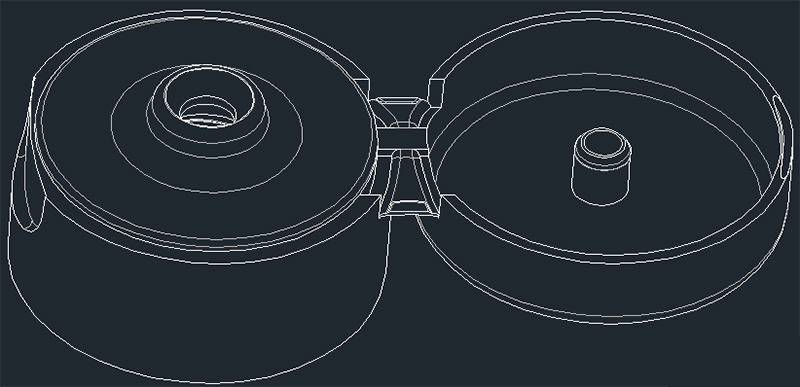

The bowknot clamshell is as shown in the figure. The material is PP which is 15 % in the shrinkage rate . PP is a crystalline plastic, and the material has good flexibility and a high expansion rate. It has good fluidity, low moisture absorption, and good folding resistance, but its molding shrinkage range is large, the shrinkage rate is large, and it is prone to shrinkage, dents, deformation, and strong directionality. Based on these factors, the molding parameters should be strictly controlled during the injection.

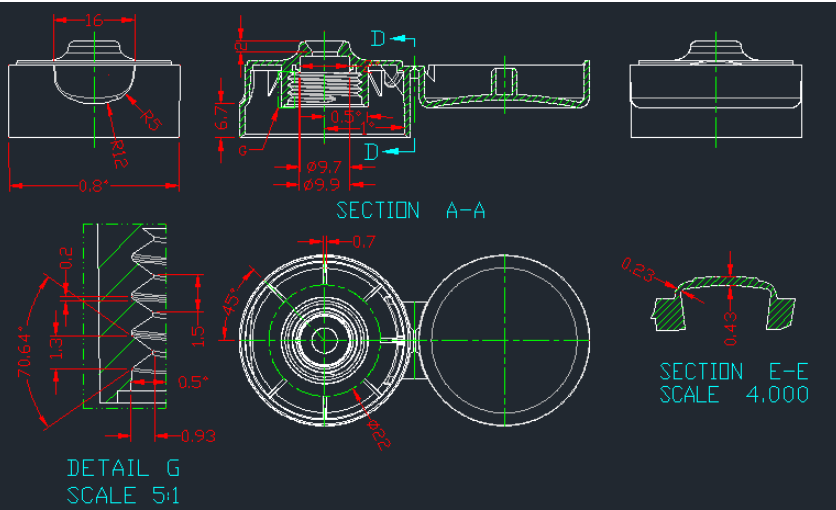

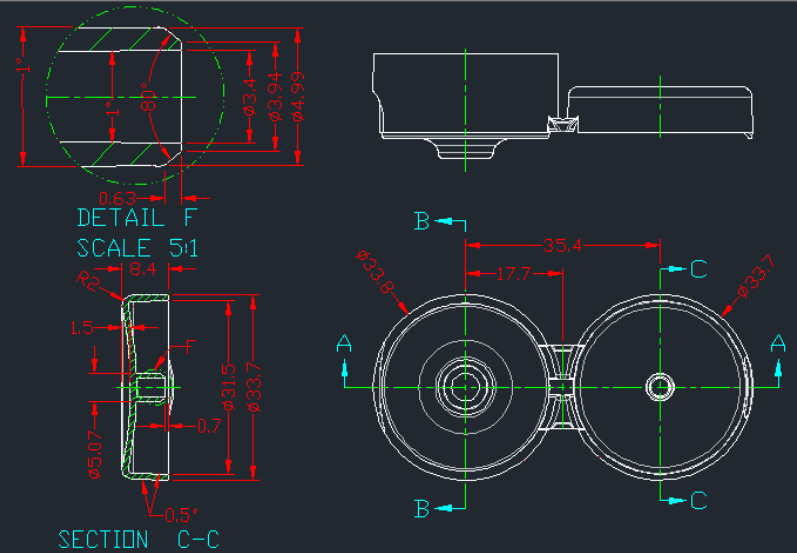

The parts of the product are divided into upper and lower covers, and the connection of the upper and lower covers is a typical plastic hinge connection, which is similar to a butterfly shape, so it is called a bow flap. This kind of flap can be opened and closed multiple times and needs to be molded once. It is widely used in shampoos and shower gel and other detergents. In order to improve the aesthetics of the product and prevent liquid from spilling, the mouth of the lower cover has ring-shaped ribs, and the small holes of the upper and lower covers are precisely matched. The appearance is required to be smooth, and no obvious parting surface joints are allowed. When the upper cover is opened and closed, it needs to be flexible, with a proper feel and tightness, and be in place automatically. The elasticity of each plastic part is balanced and the appearance is good.

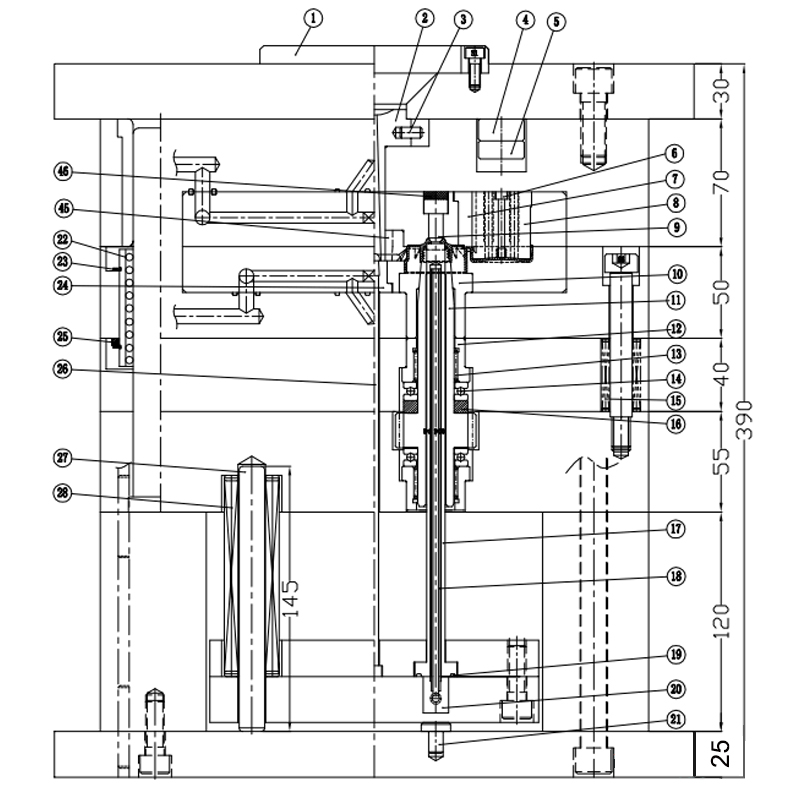

2. Mould design plan

(1)Plastic parts are large-volume products. To avoid feeding marks on the surface of the plastic parts and ensure uniform feeding, the mold adopts latent gate feeding, and the gate position is selected at the lower cover part of the upper and lower cover buckle. The glue point is not obvious after the product is closed.

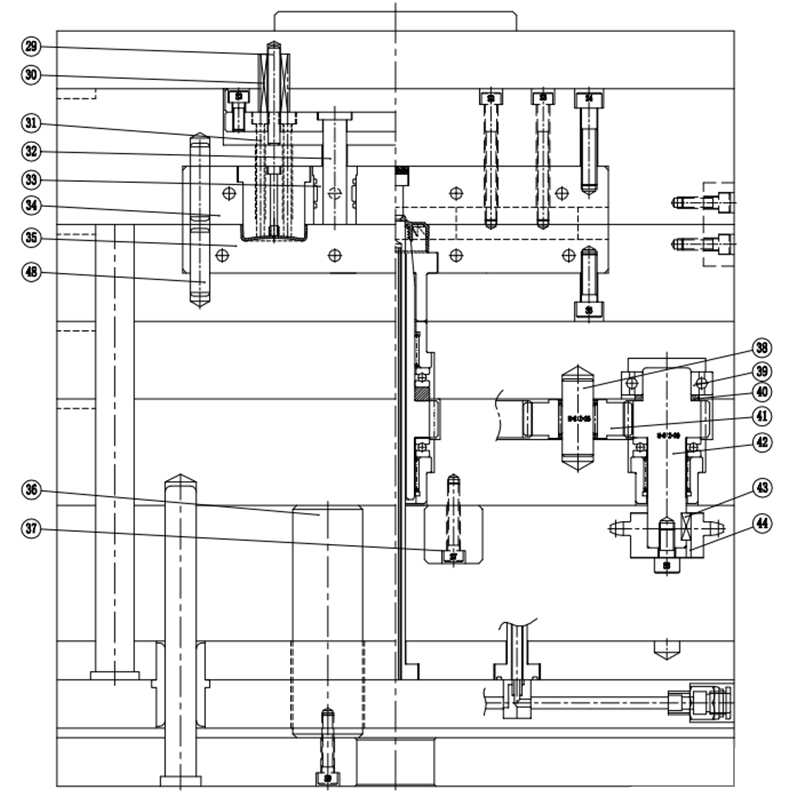

(2) To avoid joint marks on the surface of the plastic part, the upper and lower cover contour parts of the plastic part are all designed in the movable mold. The selection of the parting surface is shown in the mold diagram. Since the inner surface of the upper cover is in the fixed mold, the product will stick to the mold when the mold is opened, so the ejection structure is designed in the fixed mold. The three cavities share a set of ejector plates, and each cavity is fixed with four ejector pins 31. The ejection of the fixed mold ejector plate depends on the elastic force of the yellow spring 30, and the return of the fixed mold ejector plate relies on the return pin 32 to push the plate back.

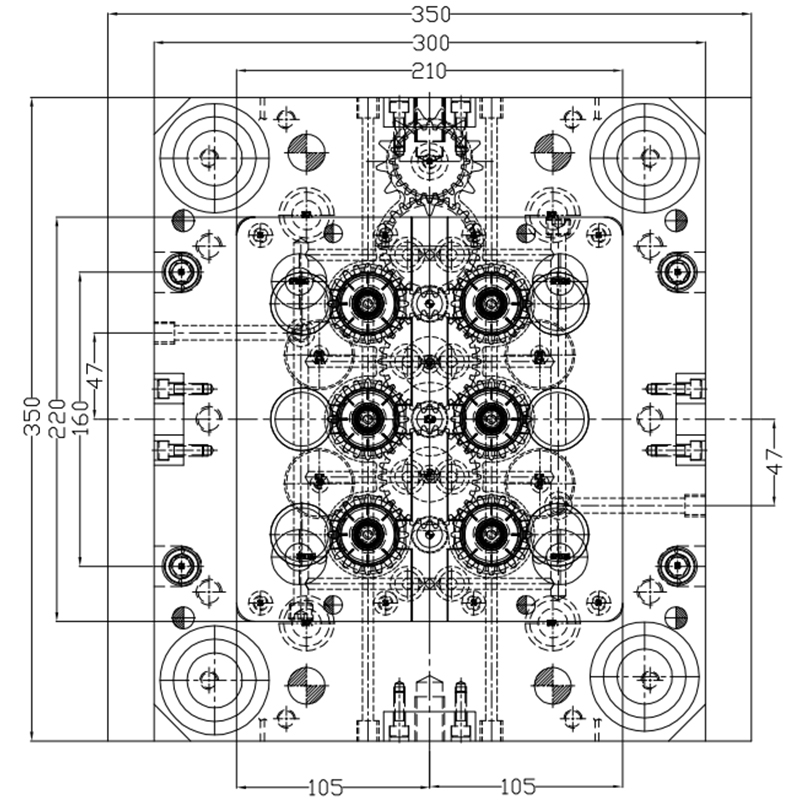

(3) Since the movable mold of the lower cover of the plastic part has threads, a hydraulic motor is designed to unthread the threads, and the threads are unloaded through the size gear drive.

(4) Mold ranking is 1*6, which can meet the requirements of mass production.

(5) To ensure the accuracy of dynamic and fixed mold clamping, four precision positioning side locks are designed on the four sides of the mold blank to guide the mold.

(6) The push plate is designed with a ball guide sleeve, and the guide column adopts an oil-free groove type linear guide column for precise guidance.

(7) The movable and fixed mold core is designed for sufficient water transportation, and there is a cooling water pipe in the movable inner mold insert to ensure the cooling effect.

(8) The mold uses standard gears with a module of 2, and the bearings also use standard parts for easy maintenance.

3. Mould action analysis

When the mold is opened, the parting surface is opened, the product follows the movable mold, the cycloid hydraulic motor is activated, and the rotating core rotates to drive the product out of the mold through the gear transmission, and the push plate ejects at the same time. The nozzle material is ejected through the thimble to complete an injection cycle.

4. Summary

The practice after production has proved that the mold design is reasonable and fully meets the requirements of mass production. It can be used as a reference when designing similar molds.