Different from the export of ordinary goods, although the export destinations of molds made in China are very wide, as far as Europe, North America, the Middle East, and as far as Southeast Asia, Japan, and South Korea, these countries and regions are all export destinations for Chinese molds. The export of molds in our industry generally refers to molds exported to Europe, North America, Japan, South Korea and other countries and regions.

According to the different design concepts and styles of the molds, the current export molds can be simply divided into three categories, that is, the three standard systems. Japan and Korea in Asia, and even Taiwan, my country, have mold styles that are very similar to mold standards. The Japanese standard is adopted, and the representative one is the MISUMI standard. The measurement unit adopts the metric system and mainly uses soft molds. The molding cycle is relatively short, and the product is updated quickly. Except for some large companies, the popularity of hot runners is low, and the cost-effectiveness of molds is higher.

In European countries such as Britain, Germany, France, Italy and the Netherlands, molds adopt European standards. The most representative one is the German HASCO standard. Each country has its own standard. For example, the United Kingdom has the DMS standard and France has the RABOURDIN standard., But these standards are not only different from HASCO standards, but somewhere also similar. For example, when ordering HASCO standard mold blanks, guide posts, guide sleeves, templates and other components are all supplied as single parts. The panels and bottom plates of each set of mold blanks can be selected from the same parts or different, with positioning For ring holes, there are installation holes without positioning rings. After purchasing these parts, you need to assemble them into molds.

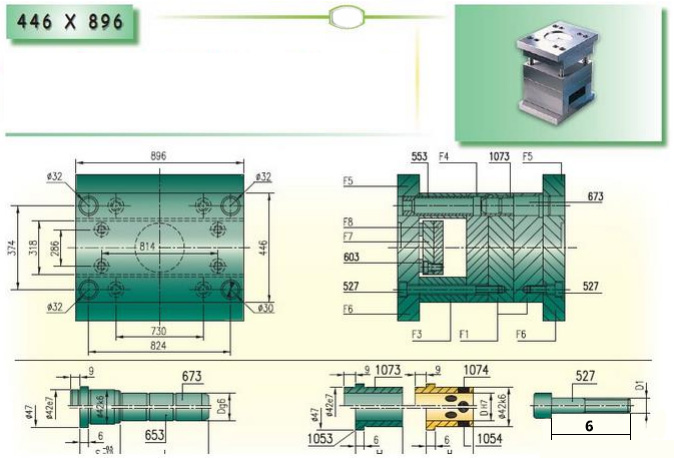

In Europe, many molds have positioning rings on the panel and bottom plate, and these characteristics are different from domestic molds. Figure below shows a set of RABOURDIN standard mold blanks. It can be seen that the panel F5 and the bottom plate F5 are exactly the same. The diameter of the guide post and guide sleeve is 3 large and 1 small, the large is 32, and the small is 30. The length and width of the template are both With 6, the guidepost and guide sleeve of the mold base is equipped with positioning function, which is similar to HASCO. The mold components are all metric standard, and the water connector is also metric thread.

The mold components are all metric standard, and the water connector is also metric thread.

The design concept of European molds is that the nozzle material is automatically cut in the mold, and manual cutting materials must not be used. Injection molding must be fully automated. Therefore, molds with fine nozzles for three-plate molds are very rare. The most commonly used are diving and horn glue (also called banana into water), because these two kinds of glue can be automatically cut off in the mold. Most of the molds on the top of the product are filled with a single hot nozzle mold or hot runner solution. HASCO, RABOURDIN, DMS and other standard mold suppliers are also developers of hot runner technology.

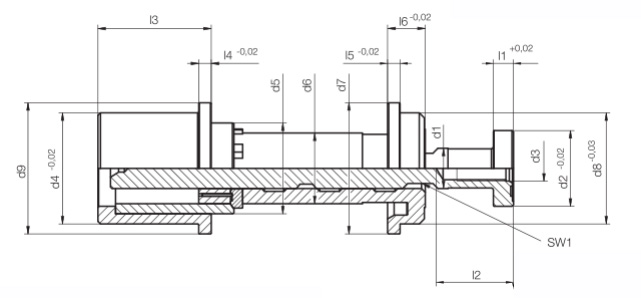

In Europe, the pursuit of high-efficiency, precision and long-life operation of molds, molds are regarded as works of art, and mold accessories are also quite exquisite. Most European molds are hard molds, and heat treatment improves the performance of steel. The factories of standard parts manufacturers such as HASCO, RABOURDIN, DMS and MEUSBURGER (Austrian brand) are not large, and the number of employees is generally five to six hundred. They attach great importance to R&D and technological innovation, and develop very rapidly, which effectively promotes mold standardization. development of. Figure below shows the new secondary ejector standard component Z1698 launched by HASCO in recent years.

The third major standard system for exporting molds is North American molds, including the United States, Canada, and Colombia. The only thing that North American molds are the same or similar to European molds is that North American molds are mainly hard molds, and the three-plate molds with small nozzles are rarely used. , Hot runners and hot nozzles are more popular, and the mold blanks are all guideposts in the fixed mold. In addition, no matter from other angles, there are big differences between North American molds and European molds.

In fact, there are few similarities between European and American molds and cannot be collectively referred to as European and American molds.

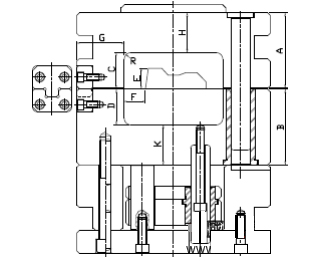

Plastic molds exported to the United States are high-end commodity molds. The most famous mold standard parts suppliers are DME, PCS and Progressive. These three standard parts systems are widely used in North American countries such as the United States, Canada and Colombia. The specific selection needs to be based on customers' Designation. The mold base of the North American mold is a straight mold base, as shown in the figure below.

DME standard molds are divided into 5 series, A, B, X, AX and T. A series and B series are the most common two-plate mold blanks, X series are used for push plate molds, AX series are similar to the simplified nozzle of Longji mold blanks, and T series are used for three-plate molds. Three-plate molds are replaced by hot runners due to the waste of plastic raw materials caused by nozzle materials. Therefore, three-plate molds account for less than 2% of the entire injection mold, and T series mold blanks are less used. American molds are usually inch molds, and the dimensions need to be in inch system. All mold blanks are H-shaped straight mold blanks. The seconed figure shows the mold blank of the B series. The front mold has only one template, and its guide post is inverted. It is used in the mold structure of the two-plate mold. The design of the mold blank has high strength and rigidity. The guide post of the DME mold blank does not have an oil groove, and the oil groove is opened on the inner wall of the guide sleeve, which is convenient for oil storage and pollution. At the same time, there is an oil injection hole on the circumference of the guide sleeve. The four sides of the mold base need to be designed with zero-degree positioning blocks instead of inclined positioning blocks.

The American D-M-E company, with a history of nearly 70 years, mainly produces standard mold parts and hot runner systems. With the continuous expansion of production and sales, it has become the world's largest mold standard parts manufacturer in the world's mold industry, and it is the world's three largest mold industry One of the standards and one of the high-end hot runner solution providers. The company's mold standard product sales network covers more than 70 countries around the world. Since the American D-M-E Company acquired the European EOC Company, D-M-E Company has become the only global mold standard parts provider that has both North American standards and European standards. At the same time, DME provides the most widely used standard mold base and MUD quick change mold base system in North America.