how can we help you

Moulds, various moulds and tools are used to obtain the required products by methods such as injection molding in industrial production, blow moulding, extrusion, die-casting or forging moulding, smelting, and stamping. In simple words, a mould is a tool used to make moulded objects. This tool is composed of various parts, and different moulds are composed of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. Therefore, it is called “the mother of industry”.

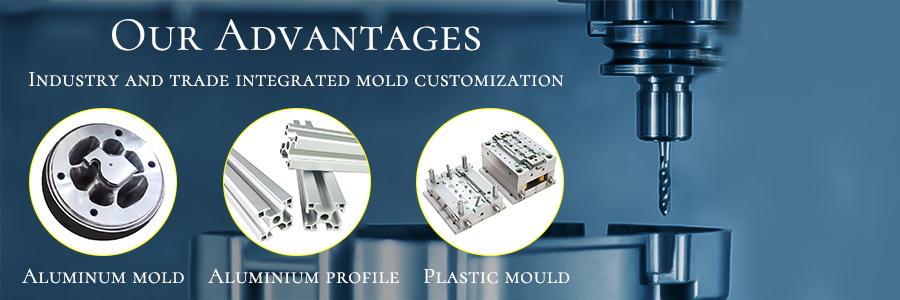

There are many types of moulds, which can be divided into:

1.Die for processing metal.

2.Processing non-metal and powder metallurgy moulds. Including plastic molds (such as two-color molds, compression molds, and extrusion molds, etc.), rubber moulds, and powder metallurgy molds. According to the structural characteristics, the mould can be divided into a flat punching mold and a cavity mold with space. Moulds are generally single-piece, small-batch production.

A mould is a model. Products are made according to this model, but how the mould is produced, maybe most of people can't answer except for mold professionals. The mold has played an irreplaceable role in our lives, most of our daily necessities are inseparable from moulds, such as computers, telephones, fax machines, keyboards, cups, etc. Needless to say, cups and other plastic products. In addition, In addition, the outer covers of cars and motorcycle engines are also made of moulds. More than 20,000 moulds are used for a single car. Therefore, the role of modern life molds is irreplaceable. As long as mass production is inseparable from moulds.